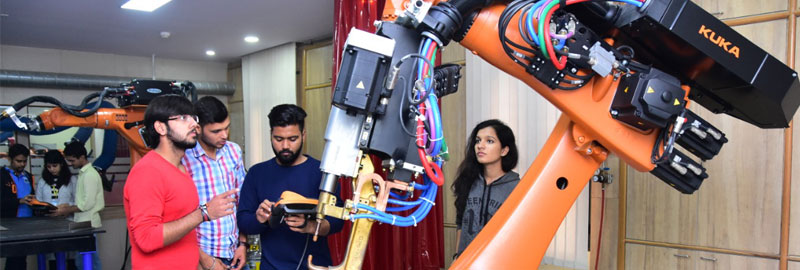

Robotic Application Programming–SPOT Welding

Spot welding process is used primarily in the automotive industry. The aim of this training is for the participants to acquire specific skill for spot welding Operation. This training provides opportunity to learn basic concept of robotic SPOT Welding programming using KUKA KR-180 robot equipped with Denyo SPOT Welding gun.

Target Group

Supervisor, Engineers, Robot Programmers, Project Manager

Duration

One Week Program | 40 Hrs

Course Outline

- Safety instruction of industrial robots.

- Recapitulation of basic training: Tool & Base Calibration; Motion Programming

- Basic concept of spot welding operation & process cycle

- Description of Servogun & Controller

- Importance of welding parameter

- Configuration of I/O signal for operation

- Description of teach box & program sequence

- Spot gun mastering &calibration

- Programming using Sevogun command

- Role of tip dresser and its programming

- Display and exporting data from weld timer

- Welding quality and its inspection technique

- Identify welding process defects / Troubleshooting

- Q & A Session

- Training test & feedback session

Key Take Aways

- Gain the knowledge of spot welding operation

- Use of Servo Gun for controlling Spot welding gun

- Understand the need of peripheral equipment required for operation i.e. tip dresser, teach box etc.

- Practical hands-on of Robotic Spot welding operation and troubleshooting.

Mode of Training

Regular : Mon – Fri (9:00 am – 5:00 pm)

Part Time : Mon – Fri (5:00 pm – 7:00 pm)

Weekend : Sat – Sun (9:00 am – 5:00 pm)

Click Here for Details of other Programs

Training | Workshop | Internship

Further Information

+91-9999930502 | +91-9891984680